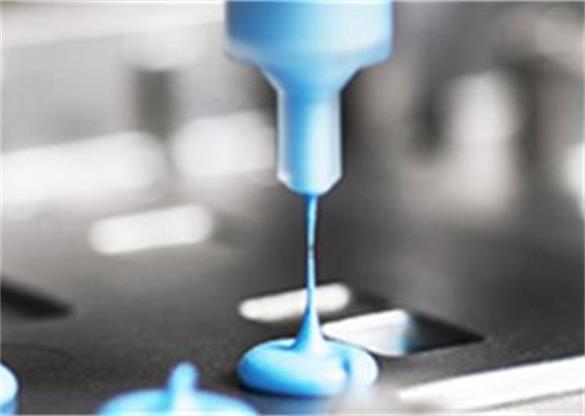

CVD(Chemical Vapor Deposition),also knows as parylene coating or nano coating.CVD is a technology that is a deposition method used to produce high quality,high-performance,solid materials.The process is often used in the semiconductor industry to produce thin films(0.1-100um).In typical CVD,the part is exposed to one or more volatile precursors,which react and/or decompose on the part surface to produce the desired deposit.Frequently,volatile by-products are also produced,which are removed by gas flow through the reaction chamber.The coating is uniform in thickness, compact without pinhole,transparent without stress and without auxiliary agent, and has excellent electrical insulation and protection. It is the most effective anti-moisture,anti-mildew, anti-corrosion and anti-salt fog coating material.

CVD Process

After the coating, the electronics will have high-dielectric strength and excellent resistance to high and low temperature(-100-200 degree C), anti-corrosion, acid and alkali resistant, lubricating, resistant to dust, moisture and rust. It is a transparent and water proof (IP68), anti-aging, biocompatible material.

LPMS designed CVD equipment and used it in the electronics industry. We provide turnkey solution from material,technology and equipment. CVD is wildly used in aviation, PCBA, LED, magnetic material, sensors, silicon rubber, sealing element, medical equipment, precious cultural relics and etc.

|

|

|

|

After CVD coating, the product has high surface chemical purity, uniform coating, no holes, no bubble, no peeling, no thermal stress.

What Can We Do?

Provide professional and feasible CVD solutions for customer specific projects and Nano-coating processing services.

Provide powder and raw materials for CVD process according to customer's technical requirements and professional technical guidance.

Provide CVD equipment (CVD vacuum coating machine, vacuum degassing furnace and other related equipment).

CVD is wildly used in aviation, PCBA, LED, magnetic material, sensors, silicon rubber, sealing element, medical equipment, precious cultural relics and etc.

CVD uses a long chain protective polymer material called parylene. It can be deposited in vacuum. The good penetrating power of the active molecule can form no pinhole around the bottom of the element and transparent insulating coating of uniform thickness provides high quality protective coating for the component. Resist the damage of acid-base salt spray and various corrosive gas. Because the liquid is not used, there is no aggregation in the coating process, and the bridge forms the meniscus. Macromolecular materials can be classified as N type、C type、 D type、F type and HT type according to their molecular structure.

Raw material grades Film forming property | CAT N type | CAT C type | CAT D type | CAT F(VT4) type | CAT AF4(HT) type |

Density(gm/cc) | 1.1 | 1.3 | 1.41 | 1.55 | 1.5 |

Dielectric constant(1Mhz) | 2.6 | 2.9 | 2.8 | 2.3 | 2.2 |

Dielectric strength(V/Mil) | 7000 | 5600 | 5500 | 5000 | 7000 |

Minimum continuous working temperature(in the air) | -60°C | -60°C | -60°C | -60°C | -60°C |

Maximum continuous working temperature(in the air) | 60°C | 80°C | 110°C | 200°C | 300°C |

Friction coefficient-dynamic condition | 0.25 | 0.29 | 0.38 | 0.39 | 0.16 |

Coefficient of linear expansion (ppm at 25°C) | 69 | 35 | 38 | 45 | 34 |

Hydroscopicity(after 24H) | <% 0.1 | <% 0.1 | <% 0.1 | <% 0.1 | <% 0.1 |

WVTR (gm.mm)/m2.day) | 0.6 | 0.08-0.1 | 0.1 | 0.25-0.32 | 0.2 |

OTR (cc.mm)/(m2.day.atm) | 16 | 3 | 12.0-13.5 | 16.8 | 25.3 |

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.